Welding Methods For Geomembranes

Twin Wedge Welding

Hot air twin wedge welding consists of placing a heated wedge, mounted on a self propelled unit, between two over-lapped sheets such that the surface of both sheets are heated above the membranes melting point. After being heated by the wedge, the overlapped panels pass through a set of pre-set pressure rollers, which compress the two sheets together to form a weld. The fusion welder is equipped with a temperature readout device that continuously monitors the temperature of the wedge.

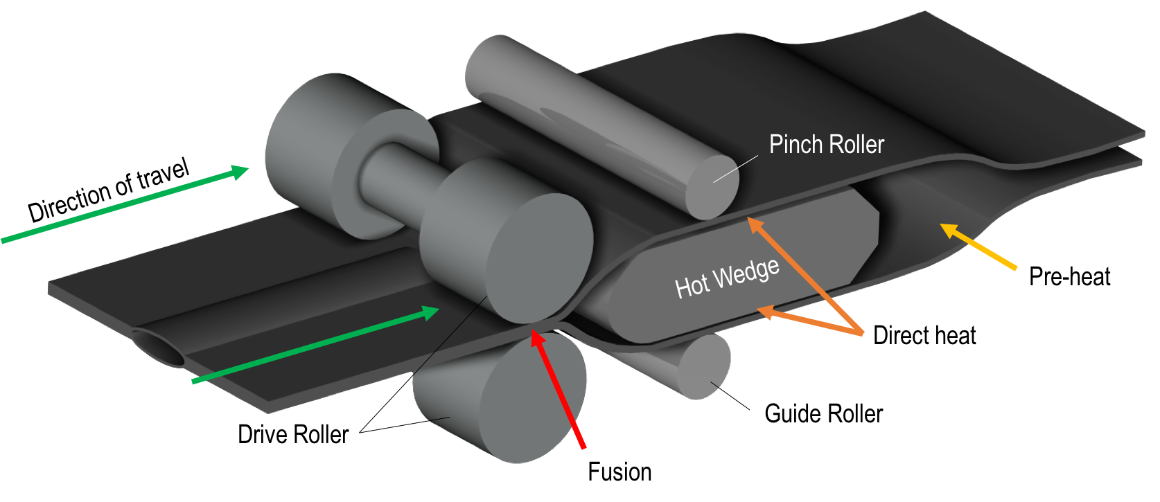

Left: Preparing the membrane prior to welding. The membrane edges are overlapped by 100mm, cleaned, and dried. Right: Welding the geomembrane. The hot wedge is moved into place and both the guide and pinch rollers are clamped down. Once clamped, the self propelled motor is engaged, and the welder will track along the membrane edge forming a twin seal weld.

Above: Illustration of welding mechanism. Lapped membrane edges are pre-heated by the hot wedge. Pre-heating the membrane primes the materials and helps to form a stronger weld. As the welder tracks along, pre-heated sections are then exposed to direct heat from the hot wedge. Pinch rollers help to ensure the material has constant contact with the hot wedge for an even heat distribution. Finally, the membrane edges are fused together by the drive rollers, forming a twin seal.

Twin Wedge Welded Seam Testing

The welded seam created by a hot air wedge welder is composed of a primary seam and a secondary track that creates an unwelded channel. This unwelded channel allows the completed weld to be tested by inflating the sealed channel with air to a predetermined pressure usually 1 bar for 5 minutes duration and observing the stability of the pressurised channel over time. For further information please consult “geosynthetics and welded gas resistant membrane installation quality plan”.

Left: Clamping the membrane in preparation for pressure testing. Right: Pressure testing twin sealed welds. The voided channel, formed by the welder, is usually inflated to 1 bar for a duration of 5 minutes. Pressure testing is witnessed by designated site personell and all quality asurance documents are signed.

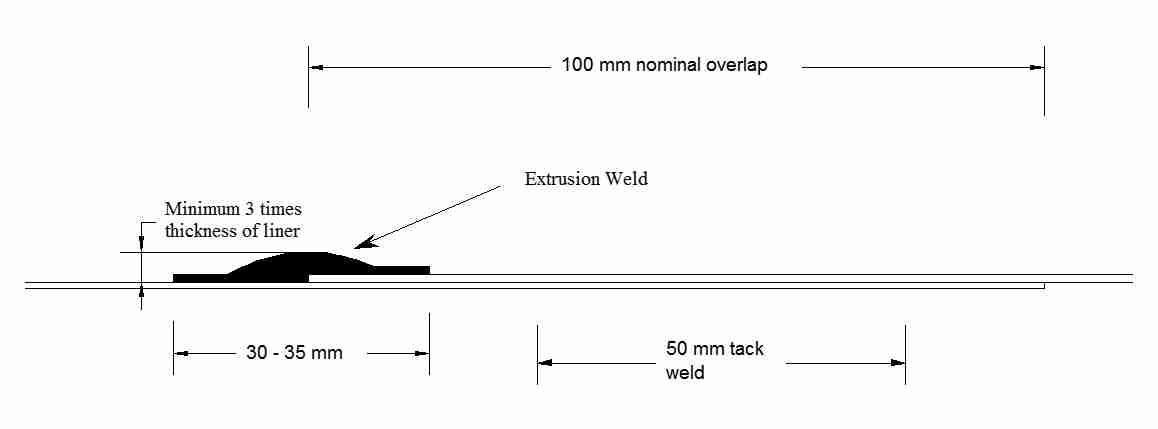

Extrusion Welding

Extrusion welding consists of introducing molten resin along the seam of the two overlapping sheets to be welded. Pre-heating of the laps and the molten polymer causes some of the material of each sheet to melt resulting in a homogeneous bond between the molten weld bead and the surfaces of the sheets.

Extrusion Welded Seam Testing

If requested prior to membrane installation, spark testing can be used for non - destructive testing of extrusion welds. After seam preparation, but prior to welding, a length of copper wire can be embedded into the seam over its entire length, after the completed weld has cooled the suitably adjusted spark tester ( 10 Kv / mm ) shall be passed over the extruded weld, any sparks observed indicate a seam failure, these should be marked on the seam. For repair at a later stage and then retested. For further information please consult “geosynthetics and welded gas resistant membrane installation quality plan”

Hot Air Welding

In areas inaccessible to the previous noted forms of welding or where site conditions dictate, overlap welds may be effected with the use of proprietary hot air guns and hand rollers. The equipment used must be specifically designed for the purpose with multi-stage variable adjustment on both heat and blower settings. The overlapped membrane is heated to softening point and fused together using the hand rollers to form a homogeneous fusion welded joint over a minimum width of 50mm.

Hot Air Welded Seam testing

Hot air welded joints may be tested using the Air Lance Method. A compressed air source will deliver 55 PSI minimum to a 5mm nozzle. The nozzle will be directed to the lip of the field seam in a near perpendicular direction to the length of the field seam. The nozzle will be held 100mm maximum from the seam and traversed at a rate not exceeding 12m per minute. Any loose flaps of 3mm or greater will require repair.